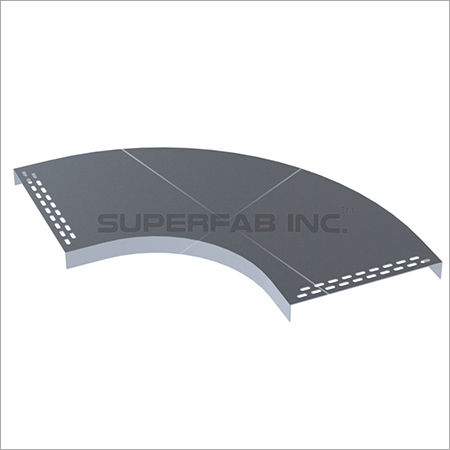

Cable Tray Cover Horizontal Elbow

Product Details:

- Control System Manual Placement

- Automation Grade Manual / Semi-Automatic

- Operating Pressure Atmospheric

- Machine Type Sheet Metal Fabrication

- Accuracy Precision Formed to Fit Elbow Profiles

- Accessories Type Cable Tray Fitting

- Technology Formed Bending

- Click to View more

X

Cable Tray Cover Horizontal Elbow Product Specifications

- Manual Placement

- Manual / Semi-Automatic

- Atmospheric

- N.A.

- Protects cables housed in horizontal elbow sections

- Sheet Metal Fabrication

- Mild Steel / Stainless Steel / Aluminum

- Precision Formed to Fit Elbow Profiles

- Cable Tray Fitting

- Cable Management in Industrial, Commercial and Utility settings

- Formed Bending

- Corrosion Resistant, Durable, Easy Installation

- Powder Coated / Hot Dip Galvanized / Pre-Galvanized

- Horizontal Elbow Cover

Cable Tray Cover Horizontal Elbow Trade Information

- Mumbai

- Cash Against Delivery (CAD), Cheque

- 7 Week

- Yes

- Contact us for information regarding our sample policy

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- All India

Product Description

Steel or aluminum made Cable Tray Cover Horizontal Elbow is used as essential part of wiring system during installation of cable trunking. Its presence can be noticed in highway, bridges, railway lines and tunnels. Known for its exceptional structural strength, this horizontal elbow is preferred for its corrosion protected surface and good anti aging characteristics. Available in light, medium and heavy duty design based specifications, this accessory is offered with powder coated or galvanized surface and perforated edge design. Low maintenance charge and corrosion proof design are its main attributes. We are a successful supplier and manufacturer of excellent quality Horizontal Elbow Cable Tray Cover.Features:

- Made of aluminum or steel

- High strength

- Rust proof

- Low maintenance cost

Specifications:

- Radius (mm): 300, 600, 800, 900, 1000, 1200

- Width (mm): 50 - 1200

- Height (mm): 15 - 30

- Thickness (mm): 1 - 3

Versatile Protection for Cable Trays

Designed to safeguard cables in horizontal tray elbows, this cover suits diverse installation needs. Its robust build, spanning multiple materials and finishes, ensures compatibility with varying environments, from demanding industrial sites to modern commercial facilities. The smooth-edge profile enhances safety and handling ease, combining functionality with superior protection. Reliable operation is guaranteed up to 120C, supporting essential cable infrastructure.

Customizable Options and Efficient Installation

Available in a broad width range and multiple thicknesses, this elbow cover offers tailored sizing to match standard trays. Multiple surface treatments and color choices allow for specific project requirements or aesthetic preferences. With screw or clamp mounting, the installation is quick and secure, saving time on-site while maintaining cable integrity and safety standards.

FAQs of Cable Tray Cover Horizontal Elbow:

Q: How is the Cable Tray Cover Horizontal Elbow installed?

A: The cover is designed for easy installation using screw or clamp fittings. This ensures a secure fit to the matching elbow tray section and can be accomplished with standard tools, simplifying maintenance and assembly.Q: What are the main benefits of using a horizontal elbow cover in cable management systems?

A: The cover protects cables from mechanical damage, dust, and moisture, especially at directional changes. Its corrosion-resistant and durable design helps prolong system lifespan while ensuring operator safety with smooth edges.Q: When should I opt for a powder coated or galvanized finish?

A: Choose powder coated finishes for indoor or aesthetic applications requiring color matching, while galvanized or hot dip galvanized options are ideal for environments demanding superior corrosion resistance, such as factories or outdoor installations.Q: Where can this product be used?

A: It is suitable for industrial, commercial, and utility contexts, making it versatile for manufacturing plants, office complexes, power stations, and infrastructure projects where horizontal cable turns need secure enclosure.Q: What material options are available, and how do I choose the right one?

A: You can select from mild steel, stainless steel, or aluminum. Stainless steel is ideal for highly corrosive environments, aluminum for lightweight installations, and mild steel for standard settings where cost-effectiveness is important.Q: How does the formed bending technology affect product performance?

A: Formed bending delivers precision-shaped covers that fit snugly onto horizontal elbow sections, ensuring consistent coverage and minimizing gaps for robust cable protection.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cable Tray Cover Accessories' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi