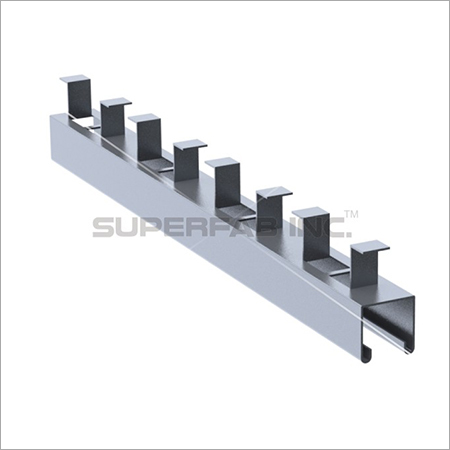

Channel Bracket 41x41

Product Details:

- Usage & Applications Commercial, industrial, infrastructure projects

- Operating Temperature -20C to +70C

- Security Features Anti-slip serrated edges

- Capacity High load bearing capacity

- Surface Finish Smooth galvanized

- Finish Type Galvanized coating

- Function Provides strong support for ducts, pipes, and cable trays

- Click to View more

Channel Bracket 41x41 Price And Quantity

Channel Bracket 41x41 Product Specifications

- Structural framing, mounting, supporting for mechanical and electrical systems

- Commercial, industrial, infrastructure projects

- Anti-slip serrated edges

- -20C to +70C

- Hot Dip Galvanized Steel

- High load bearing capacity

- Provides strong support for ducts, pipes, and cable trays

- Galvanized coating

- Smooth galvanized

- Bolt and nut assembly

- Metallic Silver

- 41x41 mm

- Direct anchor or bracket mount

- Minimum 400 MPa

- Up to 1,500 kg/m (depends on installation)

- C-channel slotted

- Static Support

- Yes

- Channel Bracket

- Hot Dip Galvanized

- Yes, due to hot dip galvanizing

- 2.9 kg/m

- Wall/ceiling/floor mount

- DIN EN 10162, ASTM A653

- Unistrut Compatible Channel Bracket 41x41

Product Description

Aluminum or pre galvanized steel made Channel Bracket 41x41 is used as framing accessory for windows and doors. Offered with hot dip galvanized or electro galvanized or powder coated surface, this metal part is offered in different thickness, length and weight options. Holes on both ends of this bracket have been created by using latest punching method. Simple installation technique, high strength, rust proof surface, oil and grease protected design, wear proof quality and high durability are its main characteristics. This accessory is offered at reasonable price range. We are an eminent supplier and manufacturer of excellent grade Channel Bracket 41x41.

Features :

- Made of steel or aluminum

- Precise diameter

- Exceptional durability

- Corrosion protected

Product details

| Thick (mm) | 2.5 mm |

| Usage/Application | Street |

| Size | 41 x 41 mm |

| Brand | Superfab Inc |

| Material | Aluminium |

| Finish | Powder Coated |

| Country of Origin | Made in India |

Superior Durability and Safety

Manufactured using cold formed steel and coated with hot dip galvanization, the Channel Bracket provides exceptional durability and resistance to corrosion. The deburred, rounded edges and anti-slip serrated features ensure safe handling and secure installation, reducing risks in demanding environments.

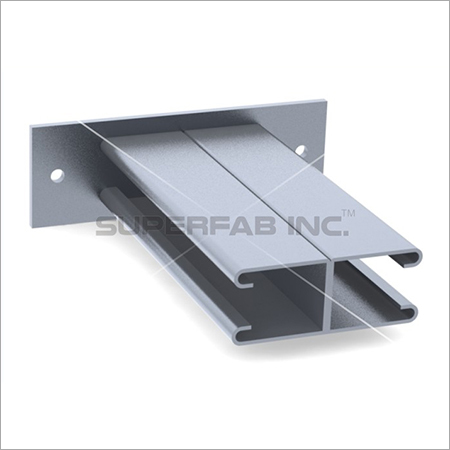

Flexible Installation and High Compatibility

The Channel Bracket 41x41 can be mounted directly onto walls, ceilings, or floors using direct anchors or bracket mounts. Its slot configuration and standard hole pitch allow seamless integration with existing Unistrut accessories, ideal for supporting ducts, pipes, or cable trays in large-scale projects.

Tailored Solutions for Challenging Applications

Available in standard and custom lengths, the bracket is designed to meet specific project requirements. Its high load-bearing capacity, non-combustible rating, and optional non-conductive coating support varied structural and electrical applications, catering to the unique needs of commercial, industrial, and infrastructure environments.

FAQs of Channel Bracket 41x41:

Q: How do I install the Channel Bracket 41x41 for wall or ceiling mount applications?

A: Installation involves securing the bracket using direct anchors or bracket mounts at the designated 50 mm hole pitch intervals. Bolt and nut assemblies ensure a firm connection to structural surfaces, supporting static loads such as ducts, pipes, and cable trays safely.Q: What are the benefits of using hot dip galvanized steel for this channel bracket?

A: Hot dip galvanization provides a smooth, corrosion-resistant coating that extends product longevity, protects against harsh weather conditions, and complies with DIN EN 10162 and ASTM A653 standards for safety and reliability in commercial and industrial settings.Q: When should I choose a custom length channel bracket over standard sizes?

A: Custom lengths are recommended when unique project specifications demand precise bracket dimensions for optimal load support or when integrating with specialized systems that cannot accommodate standard 1 m, 2 m, or 3 m sizes.Q: Where can the Channel Bracket 41x41 be used aside from structural framing?

A: This bracket is suitable for mounting, supporting, and framing mechanical and electrical systems, including in commercial, industrial, and infrastructure environments, offering reliable static support for cable trays, pipes, and ducts.Q: What manufacturing process is used for the Channel Bracket 41x41?

A: The bracket is produced by cold forming hot dip galvanized steel, ensuring a precise C-channel profile, robust structural strength with a minimum tensile of 400 MPa, and a deburred, smooth surface finish for safe handling and installation.Q: How does the non-conductive coating benefit electrical applications?

A: Upon request, the bracket can be supplied with a non-conductive coating, enhancing electrical safety by reducing the risk of accidental conductivity in installations involving live cables or sensitive electrical equipment.Q: What makes the Channel Bracket 41x41 compatible with standard Unistrut accessories?

A: Its 41x41 mm size, regular 14x36 mm slot pattern, and standardized hole pitch allow easy attachment and integration with most Unistrut accessories, streamlining project assembly and reducing installation time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Channel Brackets' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free