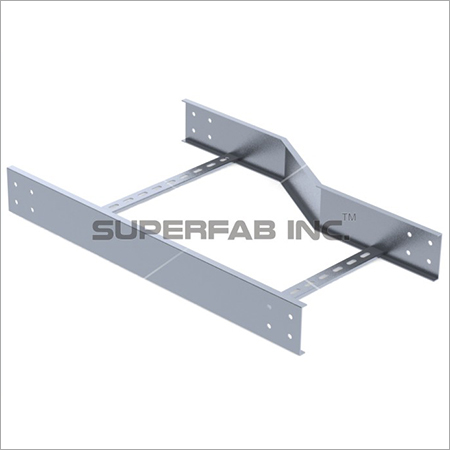

Ladder Cable Tray C Channel Inside Flange

Product Details:

- Max. Working Load Up to 150 kg/m (depends on tray size and material)

- Surface Finish Hot dip galvanized, Pre-galvanized, Powder Coated, Painted

- Conductor Material Not applicable / N.A. (non-conductive tray)

- Deflection Less than 5 mm @ full working load

- Product Type Ladder Cable Tray - C Channel with Inside Flange

- Material Mild Steel (MS), Pre-Galvanized Steel, Stainless Steel (SS304 / SS316)

- Standard Thickness 1.2 mm / 1.6 mm / 2.0 mm / 2.5 mm / 3.0 mm

- Click to View more

Ladder Cable Tray C Channel Inside Flange Price And Quantity

Ladder Cable Tray C Channel Inside Flange Product Specifications

- Less than 5 mm @ full working load

- Not applicable / N.A. (non-conductive tray)

- Silver, Grey, or as per surface finish

- 2500 mm / 3000 mm (customizable)

- 150 mm to 1000 mm (as per requirement)

- Mild Steel (MS), Pre-Galvanized Steel, Stainless Steel (SS304 / SS316)

- 1.2 mm / 1.6 mm / 2.0 mm / 2.5 mm / 3.0 mm

- Up to 150 kg/m (depends on tray size and material)

- 50 mm, 75 mm, 100 mm, 150 mm, 200 mm

- Ladder Cable Tray - C Channel with Inside Flange

- Varies as per size and material (approx. 10 kg/m to 25 kg/m)

- Custom as per order (commonly 2500 x 300 x 75 mm)

- Hot dip galvanized, Pre-galvanized, Powder Coated, Painted

Product Description

| Product Name | Ladder Cable Tray C Channel Inside Flange |

| Brand Name | SUPERFAB INC. |

| Model Number | 63 |

| Size | Customizable |

| Type | For Security Guard |

| Material | Find with various materials |

| Design | Special & various design available (Customizable) |

| Coating | According to customer |

| Certification | certified |

| FOB Price | Sent by mail |

| Main Markets | Domestic and International Market |

| Minimum Order Quantity | As per requirement |

| Place of Origin | Mumbai, Maharashtra, India |

Product details

| Height (mm) | 50 mm |

| Usage/Application | Industrial |

| Cable Tray Coating | Galvanized Coating |

| Tray Type | Ladder Type Cable Tray |

| Shape | Ladder |

| Sheet Thickness | 1.2 mm |

| Brand | Superfab Inc |

| Material | Aluminum |

| Width (mm) | 100 mm |

| Length (mm) | 2.5 m |

Specification

| Length (meters) | 2.5 / 3 |

| Width (mm) | 100 - 1500 |

| Channel Dimension (mm) | 50 x 15 x 15 |

| 50 x 20 x 20 | |

| 75 x 15 x 15 | |

| 75 x 20 x 20 | |

| 100 x 15 x 15 | |

| 100 x 20 x 20 | |

| 100 x 25 x 25 | |

| 125 x 25 x 25 | |

| 150 x 25 x 25 | |

| Rung Dimension (mm) | 30 x 15 x 15 |

| 35 x 15 x 15 | |

| 40 x 15 x 15 | |

| 40 x 20 x 20 | |

| 50 x 15 x 15 | |

| 50 x 20 x 20 | |

| Thickness (mm) | 1.2 - 3 |

Versatile Cable Management Solution

Our Ladder Cable Tray C Channel Inside Flange is engineered to efficiently support and organize electrical cables across various installation environments. Its corrosion-resistant construction and compliance with IS 8623, IEC 61537, and NEMA VE 1 standards make it ideal for challenging industrial and commercial settings. With multiple material and finish options, this tray ensures durability and adaptability for long-term cable routing.

Customizable Dimensions and Accessories

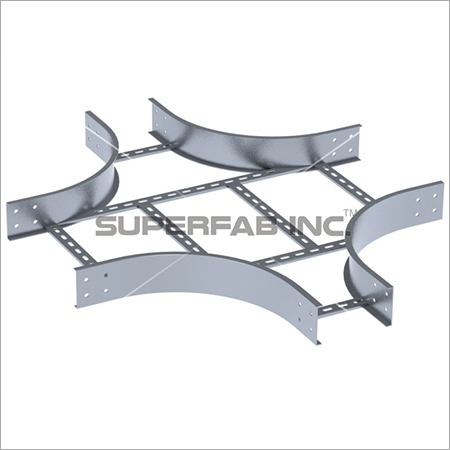

The tray is available in lengths of 2500 mm or 3000 mm and widths from 150 mm to 1000 mm, with customizable dimensions for specific project requirements. Accessories such as clamps, bends, and covers enhance flexibility in installation. Select between perforated or solid rungs to suit ventilation needs. Side rail heights and thicknesses are tailored to support different cable loads and layouts.

Reliable Performance and Safety

Designed for maximum working loads up to 150 kg/m and minimal deflection, this ladder cable tray meets rigorous safety and performance standards. Its non-conductive construction enhances electrical safety, while high fire resistance ensures compliance with stringent regulations. The smooth inside flange helps safeguard cables, promoting longevity and reducing maintenance.

FAQs of Ladder Cable Tray C Channel Inside Flange:

Q: How can the Ladder Cable Tray C Channel Inside Flange be installed for both indoor and outdoor applications?

A: This cable tray is designed to withstand varying environments due to its corrosion-resistant surface treatments such as hot dip galvanizing, pre-galvanizing, powder coating, or painting. It is suitable for both indoor and outdoor installations and can be securely mounted using supplied accessories like clamps and brackets for reliable support.Q: What are the benefits of the inside flange design on this cable tray?

A: The inside flange design enhances cable retention, providing a smooth surface that protects cables from abrasion and damage. This feature ensures cables remain securely positioned within the tray, reducing the risk of movement or wear, even in high-vibration or dynamic settings.Q: When should perforated trays be preferred over non-perforated ones?

A: Perforated trays are recommended when improved ventilation for cables is necessary or where heat dissipation is a priority. They help prevent cable overheating in densely packed installations. Non-perforated trays, however, are ideal in environments where dust protection or water ingress prevention is required.Q: Where can these ladder cable trays be used beyond industrial and commercial settings?

A: Apart from industrial plants and commercial buildings, these cable trays are suitable for use in power plants, data centers, manufacturing facilities, and extensive cable management systems where organized routing and durable support for cable runs are essential.Q: What is the process for ordering customized sizes or materials for these trays?

A: Customers can specify their required dimensions (L*W*H), material (MS, pre-galvanized steel, SS304/SS316), thickness, rail height, and accessories when placing orders. Manufacturers and suppliers in India offer customization based on project specifications and provide expert guidance on selecting the optimal configuration.Q: How do the compliance standards ensure safety and product reliability?

A: The tray adheres to IS 8623, IEC 61537, and NEMA VE 1 standards, which regulate fire resistance, load capacity, material quality, and installation safety. These standards guarantee that the product meets industry benchmarks for performance and safe cable management in critical installations.Q: What types of surface finishes are available, and how do they benefit the cable tray?

A: Surface finishes include hot dip galvanizing, pre-galvanizing, powder coating, and painting, each offering varying levels of corrosion protection and visual appeal. These finishes help increase the longevity of the tray, maintain structural integrity, and suit diverse installation environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Ladder Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free