SS Cable Trays

Product Details:

- Conductor Material Other

- Max. Working Load Up to 500 kg

- Deflection Max 5 mm at full working load

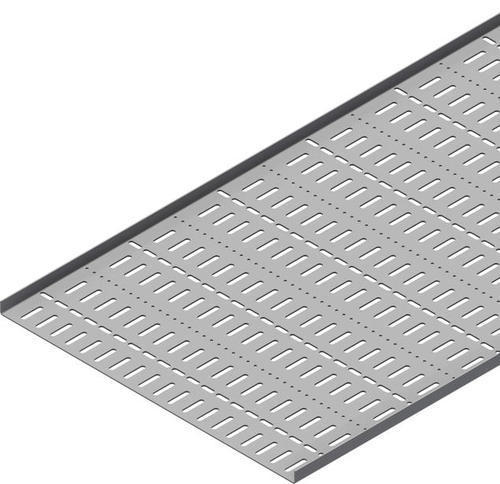

- Product Type Perforated Through

- Standard Thickness 1.2 mm, 1.6 mm Millimeter (mm)

- Length 2500 mm Millimeter (mm)

- Width 100 mm - 1200 mm Millimeter (mm)

- Click to View more

SS Cable Trays Price And Quantity

- 1000.0 INR/Meter

- 100 Piece

SS Cable Trays Product Specifications

- Max 5 mm at full working load

- Perforated Through

- 100 mm - 1200 mm Millimeter (mm)

- Up to 500 kg

- 2500-3000 Millimeter (mm)

- 50 mm - 150 mm Millimeter (mm)

- DEPENDS ON THE SIZE Kilograms (kg)

- Other

- 2500 mm Millimeter (mm)

- SS

- 1.2 mm, 1.6 mm Millimeter (mm)

- 2 YEARS

- PERFORATED

- Other

SS Cable Trays Trade Information

- 15 Days

Product Description

Notable for its perforated pattern, this SS Cable Tray is accessible in 0.5 mm to 2.0 mm thickness. This tray has maximum 75 mm height and up to 900 mm width. Length of these trays ranges between 2 m to 6 m. Simple to fix, this SS Cable Tray is used in metallurgy, telecommunication, power supplying and also in construction industries. Good heat dissipation level, standard thickness, corrosion and wear proof design are the key aspects of this cable tray.

We are leading Manufacturer, Supplier & Exporter of Stainless Steel Cable Trays. Our SS Cable Trays product range also comprises of Sheet metal parts for Switchgear, Sheet Metal Parts Gallery and Sheet Metal Parts.

Features:

- Corrosion Resistance

- Simple Usage

- Durability

Specifications:

- Material: S. Steel

- Thickness: 0.5 mm - 2.0 mm

- Height: 15 mm - 75 mm (Light, Medium, Heavy Duty)

- Width: 50 mm - 900 mm

- Length: 2 - 6 m

Superior Cable Support and Safety

Designed with regular slot perforations and rounded edges, these cable trays deliver both effective cable ventilation and optimal safety. Rounded edges prevent cable damage, while the sturdy construction provides a maximum working load of up to 500 kg. Trays are suitable for power distribution, control, and instrumentation cables.

Flexible Mounting and Customization

Our trays adapt easily to various installation scenarios, offering mounting on walls, floors, or ceilings. With custom lengths, widths, finishes, and height options available, they can be tailored perfectly to your project requirements. Accessories like covers, bends, elbows, and reducers complete your installation.

Built for Harsh Environments

Manufactured from SS 304 or SS 316 stainless steel and finished in glossy, matt, or polished silver, these trays exhibit exceptional corrosion resistance and fire safety compliance. This makes them suitable for heavy-duty applications in industrial settings exposed to moisture, harsh chemicals, and temperature variations from -20C to +120C.

FAQs of SS Cable Trays:

Q: How does the SS Cable Tray ensure cable ventilation and safety?

A: The tray is designed with regular slot perforations that enhance airflow around cables, efficiently dissipating heat. In addition, rounded edge profiles minimize the risk of abrasion or damage to cables during installation and operation.Q: What customization options are available for these cable trays?

A: You can customize length (up to 2500 mm), width (100 mm to 1200 mm), finishes (glossy, matt, polished), and side rail height (50 mm to 150 mm) to match specific project requirements. Customized packaging and a selection of accessories further enhance flexibility.Q: When should I use SS 304 versus SS 316 trays?

A: SS 304 trays are excellent for most standard environments, while SS 316 offers superior corrosion resistance, making it ideal for aggressive industrial or coastal conditions where protection from chloride exposure is essential.Q: Where can these cable trays be installed?

A: They can be mounted on walls, floors, or ceilings, enabling versatile installation across factories, substations, and industrial facilities managing power, control, and instrumentation cables.Q: What is the manufacturing process for these trays?

A: Each tray is produced using automatic CNC cutting and punching machinery, ensuring precision slot perforations and consistent quality while maintaining smooth, rounded edges.Q: How do the fire and load specifications benefit industrial applications?

A: The trays comply with standard fire safety requirements and support up to 500 kg with minimal deflection (max 5 mm under full load), offering reliable and safe cable management under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Stainless Steel Cable Trays ' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free