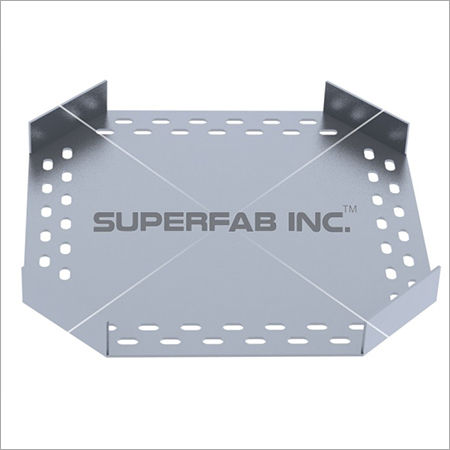

Perforated Cable Tray Cross

Product Details:

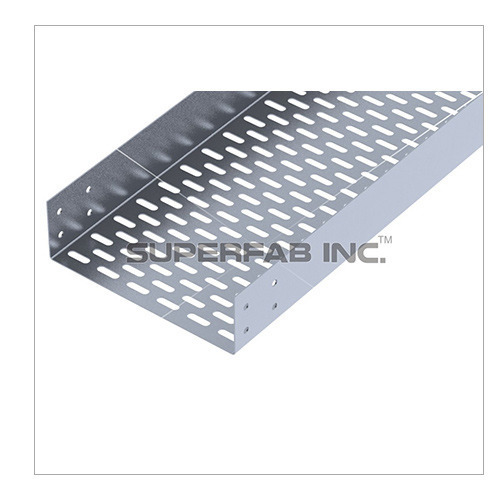

- Max. Working Load 3040 kg per meter

- Surface Finish Pre-Galvanized / Powder Coated

- Deflection <10 mm at max load

- Product Type Perforated Cable Tray Cross

- Material Mild Steel (MS)

- Standard Thickness 1.2 mm 2 mm

- Length Up to 300 mm

- Click to View more

X

Perforated Cable Tray Cross Price And Quantity

Perforated Cable Tray Cross Product Specifications

- Mild Steel (MS)

- Perforated Cable Tray Cross

- <10 mm at max load

- Approx. 2.54.5 kg

- Pre-Galvanized / Powder Coated

- Up to 300 mm

- 50 mm

- 1.2 mm 2 mm

- Up to 300 mm

- 300 mm x 300 mm x 50 mm

- 3040 kg per meter

- Silver/Grey

Product Description

Backed by our skilled team of professionals, we have been engaged in manufacturing, exporting and supplying a colossal assortment of Perforated Cable Tray Cross. This cross is manufactured at our well equipped production unit using quality tested raw materials and cutting edge techniques. Suitable for connecting cable tray, this cross is highly appreciated among customers. With commitment of on time delivery, this Perforated Cable Tray Cross can be purchased from us at pocket friendly rates.

Key Points:

- High durability

- Superior finish

- Sturdiness

- Quick installation

Product Details:

- Radius (mm): 300, 600, 800, 900, 1000, 1200

- Width (mm): 50 - 1200

- Height (mm): 15 - 150

- Thickness (mm): 1 - 3

Efficient Cable Management Solution

Designed to streamline the routing and distribution of multiple cables, the Perforated Cable Tray Cross facilitates neat organization within electrical panels or large industrial installations. Its four-way junction allows for versatile cable direction while maintaining structural integrity under load.

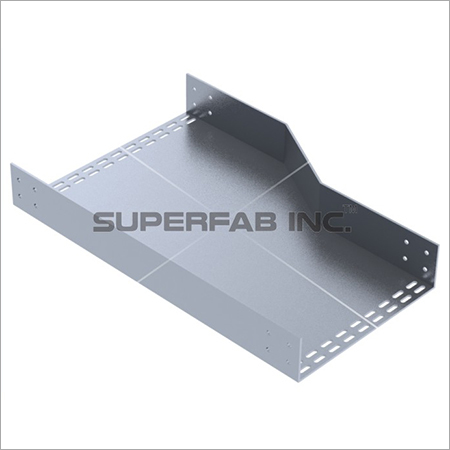

Robust and Safe Construction

Fabricated from high-quality mild steel and featuring a bend edge for enhanced safety, the tray offers both rigidity and secure handling. The uniform perforation pattern supports effective ventilation, reducing the risk of heat buildup and maintaining cable performance over time.

Versatility and Compatibility

The tray is compatible with standard cable tray fittings and accessories, making integration into existing systems straightforward. With options for mounting on either walls or floors, it suits various installation environments and requirements, adapting to multiple project specifications.

FAQs of Perforated Cable Tray Cross:

Q: How do I install the Perforated Cable Tray Cross in electrical panels or industrial sites?

A: The tray is designed for both wall and floor mounting, using compatible standard cable tray brackets and fittings. Installers should secure each arm of the cross and ensure its level before fastening cables through the uniform perforations.Q: What materials and finishes are available for this cable tray cross?

A: Manufactured from mild steel (MS), the tray offers pre-galvanized or powder-coated silver/grey finishes. Both options provide excellent corrosion resistance and durability in challenging industrial environments.Q: When is the Perforated Cable Tray Cross most beneficial in a wiring system?

A: Its most effective when multiple cable routes intersect, as in electrical panels or large wiring networks, allowing four-way cable management and reducing clutter while supporting up to 3040 kg per meter load.Q: Where should the cable tray cross be mounted for optimal performance?

A: Depending on the cable routing needs and space, it can be mounted on walls or floors. Its compact 300 mm x 300 mm footprint and uniform edge formation ensure safe placement in various site conditions.Q: What is the installation process for connecting this product with other cable tray accessories?

A: The cross junction is compatible with standard tray accessories and fittings. Align the cross with adjoining trays, secure using bolts or clamps through pre-drilled holes, and ensure edges are bent inward for safety and rigidity.Q: What advantages does the bend-edge design provide?

A: The bend-edge formation enhances safety by eliminating sharp corners, improving tray rigidity, and safeguarding both cables and personnel during installation and maintenance.Q: How does the hole pattern benefit cable performance?

A: Uniform circular perforations promote airflow and prevent heat accumulation, thereby preserving cable integrity and reducing the likelihood of overheating during extended operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi