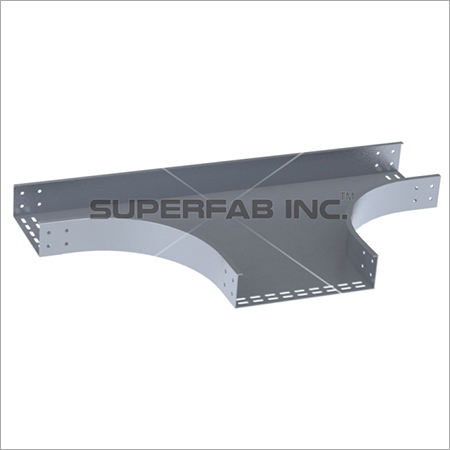

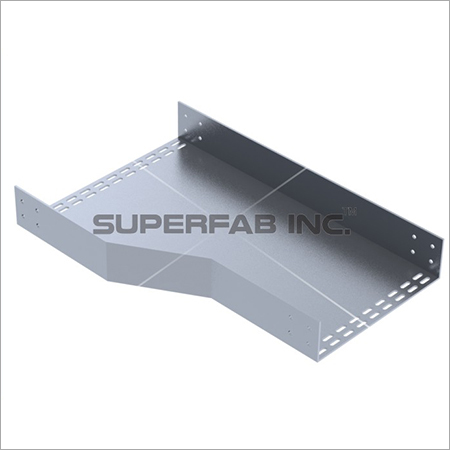

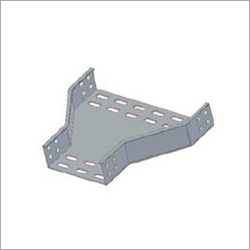

Straight Flange Perforated Cable Tray

Product Details:

- Max. Working Load 50 kg

- Conductor Material Steel

- Deflection Less than 10 mm

- Surface Finish Electro-Galvanized

- Product Type Straight Flange Perforated Cable Tray

- Material Pre-Galvanized Iron

- Standard Thickness 1.6 mm

- Click to View more

X

Straight Flange Perforated Cable Tray Product Specifications

- 3.2 kg

- Steel

- Less than 10 mm

- Pre-Galvanized Iron

- Straight Flange Perforated Cable Tray

- 50 kg

- Silver

- 2500 mm x 150 mm x 50 mm

- 2500 mm

- 150 mm

- 1.6 mm

- 50 mm

- Electro-Galvanized

Product Description

We are leading supplier and trader an extensive series of Straight Flange Perforated Cable Tray.Straight Flange Perforated Cable Tray Features:

- Longer life service

- Easy to use

- Fine finish

STANDARD SPECIFICATIONS | |

Length (meters) | 2.5 / 3 |

Width (mm) | 50 - 1200 |

Height (mm) | 15 - 150 |

Thickness (mm) | 1 - 3 |

Reliable Design for Heavy-Duty Applications

Engineered with a straight flange edge, this perforated cable tray ensures secure support for up to 60 cables. Its rectangular holes allow for efficient ventilation and cable entry while maintaining structural integrity. The zinc-coated surface and pre-galvanized iron construction provide prolonged protection in both indoor and semi-outdoor environments, making it suitable for various electrical installations.

Safety and Compliance You Can Trust

This cable tray has been rigorously manufactured to meet IS 8623 and IEC 61537 standards, guaranteeing reliability and compliance in electrical power distribution systems. The fire resistance rating up to 700C and a temperature tolerance from -20C to +80C ensure your installations remain safe and operational under demanding conditions.

FAQs of Straight Flange Perforated Cable Tray:

Q: How is the Straight Flange Perforated Cable Tray installed?

A: The cable tray is designed for easy floor or wall mounting installation. Pre-punched holes facilitate quick attachment to surfaces, making the installation process efficient for electricians and installers.Q: What is the maximum cable capacity and working load of this tray?

A: This tray accommodates up to 60 cables and has a maximum working load of 50 kg, making it suitable for medium to large-scale electrical power distribution projects.Q: Where can this cable tray be effectively used?

A: It is ideal for use in commercial, industrial, and infrastructure projects requiring robust electrical power distribution, especially where fire safety and corrosion resistance are priorities.Q: What standards does the cable tray comply with?

A: The tray complies with IS 8623 and IEC 61537 standards, ensuring it meets industry requirements for safety, quality, and performance in electrical installations.Q: How does the zinc-coated, electro-galvanized finish benefit the tray?

A: The zinc coating and electro-galvanized surface offer strong corrosion protection, significantly extending the trays service life, even in environments with moisture or chemical exposure.Q: What maintenance is required for this cable tray?

A: This product is designed for low maintenance. Routine inspections for debris or excessive load will help maintain its structural integrity and optimum performance over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free