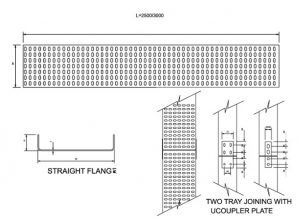

Perforated Cable Tray Outside Flange

Product Details:

- Max. Working Load Up to 100 kg/m (varies by size and thickness)

- Deflection Less than 1/100th of span under working load

- Surface Finish Hot Dip Galvanized / Pre-Galvanized / Powder Coated / Painted

- Conductor Material Metallic (as per base material)

- Product Type Perforated Cable Tray with Outside Flange

- Material Mild Steel / Pre-Galvanized Steel / Stainless Steel / Aluminum

- Standard Thickness 1.2 mm / 1.6 mm / 2.0 mm / 2.5 mm

- Click to View more

X

Perforated Cable Tray Outside Flange Price And Quantity

Perforated Cable Tray Outside Flange Product Specifications

- 25 mm to 150 mm

- 2500 mm

- 100 mm to 1000 mm

- Metallic (as per base material)

- Hot Dip Galvanized / Pre-Galvanized / Powder Coated / Painted

- Variable (depends on size and thickness)

- Less than 1/100th of span under working load

- Customizable as per requirement

- 1.2 mm / 1.6 mm / 2.0 mm / 2.5 mm

- Mild Steel / Pre-Galvanized Steel / Stainless Steel / Aluminum

- Up to 100 kg/m (varies by size and thickness)

- Silver / Grey

- Perforated Cable Tray with Outside Flange

Perforated Cable Tray Outside Flange Trade Information

- All India

Product Description

Perforated Cable Tray Outside Flange Specification :-

| Product Name | Perforated Cable Tray Outside Flange |

| Brand Name | SUPERFAB INC. |

| Model Number | 85 |

| Size | Customizable |

| Type | For Security Guard |

| Material | Find with various materials |

| Design | Special & various design available (Customizable) |

| Coating | According to customer |

| Certification | certified |

| FOB Price | Sent by mail |

| Main Markets | Domestic and International Market |

| Minimum Order Quantity | As per requirement |

| Place of Origin | Mumbai, Maharashtra, India |

Standard Specification

| Length (Meters) | 2.5/3 |

| Width (MM) | 50 1200 |

| Height (MM) | 15 150 |

| Thickness (MM) | 1 3 |

Robust Cable Management Solution

These cable trays are ideal for managing large volumes of power and data cables in demanding industrial and commercial installations. The outside flange design and perforated pattern provide enhanced structural integrity and facilitate proper heat dissipation, reducing cable overheating risk.

Versatile Installation Options

The tray can be wall-mounted, floor-mounted, or suspended, giving installers flexibility to suit the layout and requirements of each specific site. With customizable dimensions and side rail heights ranging from 25 mm to 150 mm, our trays adapt seamlessly to unique installation challenges.

Superior Durability and Compliance

Manufactured from fire-retardant, high-corrosion resistant metals, these trays are designed for enduring performance, even in humid or outdoor conditions. Compliance with IS and IEC standards ensures reliability and safety, making them a trusted choice for critical cable deployments.

FAQs of Perforated Cable Tray Outside Flange:

Q: How does the outside flange design benefit cable management?

A: The outside flange design of the cable tray offers increased structural rigidity and keeps cables secure, minimizing the risk of snagging or damage during installation and maintenance. It also allows for easier access to cables when modifications or inspections are needed.Q: What types of cable tray perforation patterns are available and why are they important?

A: Our cable trays feature standard slot and round hole patterns. These perforations improve ventilation, helping dissipate heat generated by densely packed cables, thereby reducing fire risk and prolonging cable lifespan, particularly in demanding power and data applications.Q: When and where should I use perforated cable trays with high corrosion resistance?

A: High corrosion-resistant cable trays are recommended in humid, outdoor, or chemically aggressive industrial environments where protection against rust and corrosion is essential. Typical applications include factories, refineries, outdoor installations, and areas exposed to moisture.Q: What accessories are provided with perforated cable trays?

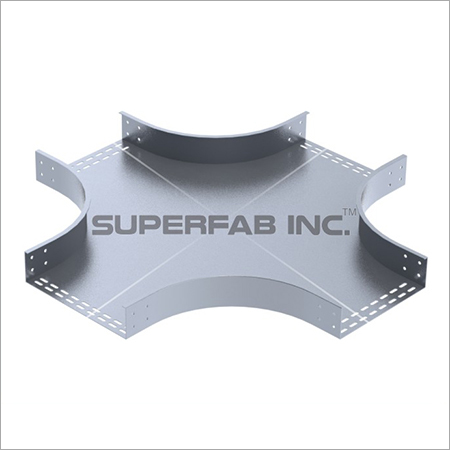

A: Accessories such as bends, tees, and covers are available to accommodate directional changes and protect cables within your installation. These can be selected based on project requirements to ensure a comprehensive, secure, and organized cable management system.Q: What is the process for customizing cable tray dimensions and finishes?

A: Customization is straightforward: you can specify your preferred length, width, side rail height, material, thickness, and finish (hot dip galvanized, pre-galvanized, powder coated, or painted). The trays are then manufactured to your exact requirements for optimal fit and performance.Q: How is fire retardancy ensured in these cable trays?

A: Fire retardancy is ensured by material selectionchoose pre-galvanized steel, stainless steel, or aluminum for superior resistance. All trays adhere to relevant safety standards, providing added protection for critical installations where fire safety is paramount.Q: What are the installation methods suitable for these cable trays?

A: The cable trays can be installed wall-mounted, floor-mounted, or suspended from ceilings. This flexibility enables use in a wide array of environments, from industrial factory floors to high-rise commercial buildings, ensuring efficient cable organization wherever needed.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free