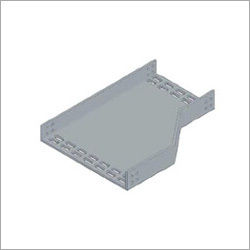

Perforated Tray Left Hand Reducer

Product Details:

- Conductor Material Steel / Aluminium

- Deflection Less than 1/200th of span under normal load

- Max. Working Load Up to 50 kg/m (depending on tray size and installation)

- Surface Finish Galvanized, Powder Coated, Painted, Plain

- Product Type Perforated Tray Left Hand Reducer

- Material Pre-Galvanized Steel, Mild Steel, Stainless Steel (SS304/SS316), Aluminium

- Standard Thickness 1.2 mm, 1.6 mm, 2.0 mm, 2.5 mm (as per requirement)

- Click to View more

X

Perforated Tray Left Hand Reducer Price And Quantity

Perforated Tray Left Hand Reducer Product Specifications

- As per order specification

- 50 mm to 1000 mm

- Galvanized, Powder Coated, Painted, Plain

- Less than 1/200th of span under normal load

- Perforated Tray Left Hand Reducer

- Up to 50 kg/m (depending on tray size and installation)

- Varies with size and material; typically 2 to 8 kg/m

- Pre-Galvanized Steel, Mild Steel, Stainless Steel (SS304/SS316), Aluminium

- 25 mm, 50 mm, 75 mm, 100 mm

- 250 mm to 3000 mm (custom sizes available)

- Steel / Aluminium

- 1.2 mm, 1.6 mm, 2.0 mm, 2.5 mm (as per requirement)

- Silver, Hot Dip Galvanized, Powder Coated (custom colors on request)

Product Description

Having both quality and clients centric approach, we have been engaged in manufacturing, exporting and supplying a premium array of Perforated Tray Left Hand Reducer. This reducer is manufactured using quality tested raw materials and sophisticated techniques by adroit professionals. Suitable for managing cables in communication sectors, this tray is highly appreciated among customers. Furthermore, we offer this Perforated Tray Left Hand Reducer to our valuable clients at industry leading rates within stipulated time frame.

Key Points:

- Supreme finish

- High durability

- Accurate dimensions

- Sturdiness

Specifications:

- Radius (mm): 300, 600, 800, 900, 1000, 1200

- Width (mm): 50 - 1200

- Height (mm): 15 - 150

- Thickness (mm): 1 - 3

Product details

| Height (mm) | 15 mm |

| Material | Steel |

| Cable Tray Coating | Powder Coated |

| Brand | Superfab Inc |

| Width (mm) | 50 mm |

| Usage | Perforated Cable Tray Accessories |

| Thickness | 2 mm |

| Radius (mm) | 300 mm |

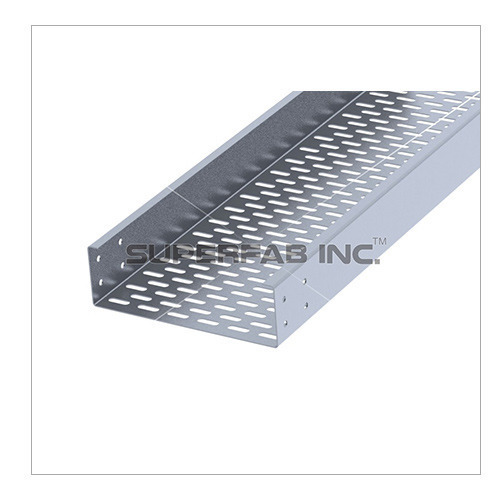

Precision Engineering for Dimensional Accuracy

Each left hand reducer is precision die-formed to ensure dimensional accuracy and seamless alignment with other tray accessories. The smooth edge bend type is specifically engineered to safeguard cables against abrasion, enhancing system longevity while maintaining safety standards.

Superior Ventilation & Corrosion Resistance

Perforation patterns, available in standard round or slot designs, promote consistent airflow to cables, preventing overheating. Multiple materials and surface finishessuch as galvanized, powder coated, or paintedenable high resistance to corrosion and environmental impact, suitable for harsh operating conditions.

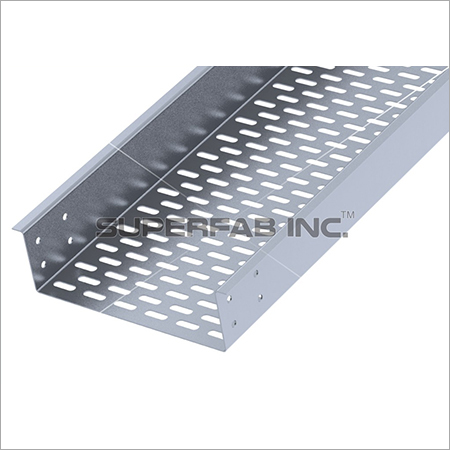

Flexible Mounting and Customization Options

These reducers can be mounted on walls, floors, or ceilings using compatible brackets and hardware. Available in lengths from 250 mm to 3000 mm and widths from 50 mm to 1000 mm, with custom sizes and finishes on request, they fit a broad array of infrastructure requirements.

FAQs of Perforated Tray Left Hand Reducer:

Q: How is the Perforated Tray Left Hand Reducer installed in various environments?

A: The reducer can be mounted on walls, floors, or ceilings using appropriate brackets and hardware provided as per project requirements. Its versatile design enables straightforward integration into commercial and industrial cable management systems.Q: What materials and finishes are available for this left hand reducer?

A: Options include pre-galvanized steel, mild steel, stainless steel (SS304/SS316), or aluminium. Surface finishes can be galvanized, powder coated, painted, or plain, with custom colors available upon request to suit specific project aesthetics or corrosion resistance needs.Q: When should I use a left hand reducer in my cable tray layout?

A: Left hand reducers are used when a cable tray system requires width reduction on the left side to accommodate space constraints, routing changes, or connection to other tray sections. They ensure a smooth transition while maintaining cable protection.Q: Where can the reducer be applied, and what are its main uses?

A: It is ideal for power distribution and cable management in commercial and industrial infrastructures, including data centers, factories, and utility installations, where efficient ventilation and corrosion protection are necessary.Q: What process ensures the reducers dimensional accuracy and quality?

A: Precision die-forming and manufacturing according to IS 1079/IS 513 and IEC standards ensure that each reducer meets strict dimensional and quality requirements, guaranteeing reliable performance and compatibility with other components.Q: How does the perforation pattern benefit cable management?

A: Standard round or slot perforations enhance ventilation, minimizing overheating risks for cables. This design also aids in moisture dissipation, helping to maintain optimal cable performance within the installation.Q: What are the main benefits of choosing this product for my project?

A: This product offers high corrosion resistance, robust load capacity (up to 50 kg/m), seamless compatibility with cable tray accessories, and options for customization. These features help maintain system safety, efficiency, and longevity in diverse environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free