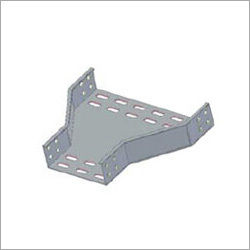

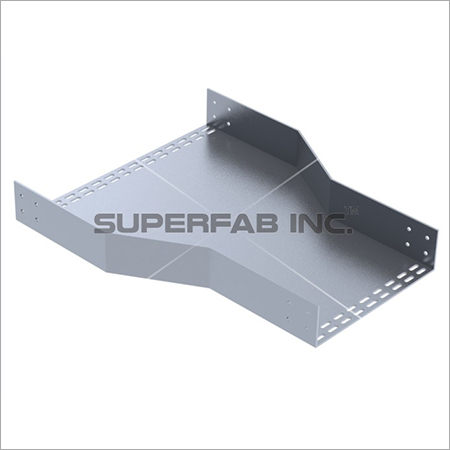

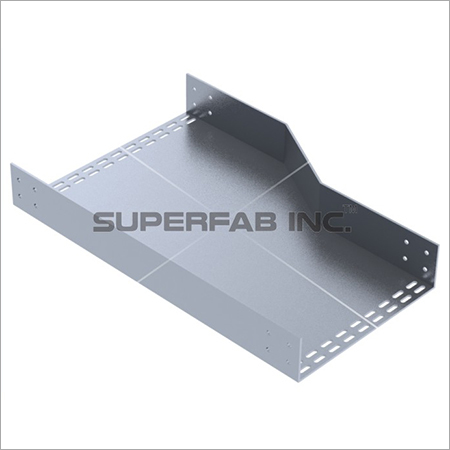

Perforated Tray Center Reducer

Product Details:

- Surface Finish Pre-Galvanized, Hot Dip Galvanized, Powder Coated, Painted

- Conductor Material Steel or Aluminum, non-conductive variants on request

- Max. Working Load Up to 50 kg per meter (depending on tray size and support span)

- Deflection Meets industry standards for tray deflection, typically <1/200th of span

- Product Type Perforated Cable Tray Center Reducer

- Material Mild Steel (MS), Pre-Galvanized Steel, Stainless Steel (SS 304/316), Aluminum

- Standard Thickness 1.2 mm, 1.6 mm, 2.0 mm, and customized as per requirement

- Click to View more

X

Perforated Tray Center Reducer Price And Quantity

Perforated Tray Center Reducer Product Specifications

- Varies with width, height, and material; typically 2 - 10 kg per piece

- Up to 50 kg per meter (depending on tray size and support span)

- Silver, Powder-coated options available

- Meets industry standards for tray deflection, typically <1/200th of span

- Pre-Galvanized, Hot Dip Galvanized, Powder Coated, Painted

- Customizable as required (e.g., 2500 mm x 300 mm x 50 mm)

- 25 mm, 50 mm, 75 mm, 100 mm

- 1.2 mm, 1.6 mm, 2.0 mm, and customized as per requirement

- Available in standard 2.5 meters and custom lengths upon request

- 50 mm to 600 mm

- Perforated Cable Tray Center Reducer

- Steel or Aluminum, non-conductive variants on request

- Mild Steel (MS), Pre-Galvanized Steel, Stainless Steel (SS 304/316), Aluminum

Product Description

Being in this domain since 2007, we have been engaged in manufacturing, exporting and supplying a premium array of Perforated Tray Center Reducer. This reducer is manufactured using top quality raw materials and sophisticated techniques by ingenious professionals. In order to lay cables in a planned way, this reducer is highly appreciated among customers. Examined on various quality parameters prior dispatch, this Perforated Tray Center Reducer can be purchased from us at most economical rates within stipulated time frame.

Key Points:

- Supreme finish

- Rugged design

- Easy installation

- Rust resistance

Product details

| Brand | Superfab Inc |

| Material | Aluminium |

| Cable Tray Coating | Galvanized Coating |

| Width (mm) | 50 mm |

| Usage | Perforated Cable Tray Accessories |

| Thickness | 1 mm |

| Radius | 300 mm |

| Height (mm) | 15 mm |

Specifications:

- Radius (mm): 300, 600, 800, 900, 1000, 1200

- Width (mm): 50 - 1200

- Height (mm): 15 - 150

- Thickness (mm): 1 - 3

Center Reducer: Versatility and Compatibility

Engineered for adaptability, the center reducer connects cable trays of varying widths in a unified cable management system. With bolt or coupler plate joining, it supports robust installation and quick assembly. This feature ensures compatibility with covers, bends, tees, risers, and other tray fittings.

Quality Materials and Surface Finishes

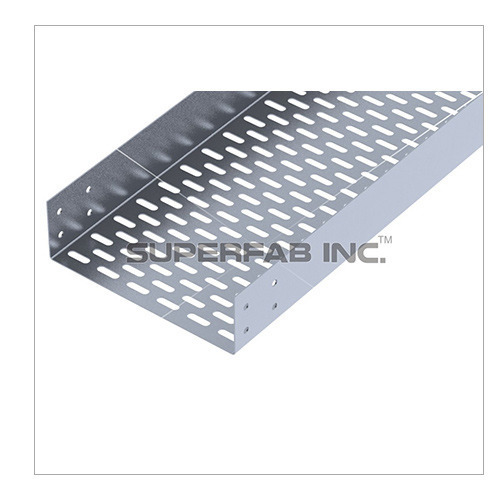

Manufactured from mild steel, pre-galvanized steel, stainless steel (304/316), or aluminum, these reducers deliver durability and high corrosion resistance. Surface finish options include pre-galvanized, hot dip galvanized, powder-coated, and painted, providing protection against challenging conditions and fire hazards.

Standards and Safety Assurance

With adherence to IS, IEC, and NEMA standards, each center reducer meets rigorous industry requirements. Smooth de-burred edges prevent cable damage, and standard rectangular perforations support ventilation and cable fixing, ensuring operational reliability and safety across various environments.

FAQs of Perforated Tray Center Reducer:

Q: How is the Perforated Tray Center Reducer typically installed in a cable tray system?

A: Installation is accomplished using bolt connections or coupler plates, allowing secure attachment between cable trays of differing widths. For best results, ensure all connections are tightened properly and accessories such as covers, bends, or tees are integrated as required.Q: What are the main benefits of standard rectangular perforations in these reducers?

A: Standard rectangular perforations facilitate effective ventilation and allow for secure cable fixing. This design feature helps reduce heat buildup and enables easy attachment of cables or other tray-mounted equipment.Q: What materials are available for the Perforated Tray Center Reducer, and how does this affect corrosion resistance?

A: The reducer can be manufactured from mild steel, pre-galvanized steel, stainless steel 304/316, or aluminum. Corrosion resistance is considerably improved by surface treatments such as galvanizing, painting, or powder-coating, making it suitable for harsh environments.Q: When should a fire-resistant surface finish be considered for these tray reducers?

A: Fire-resistant surface finishes are recommended in installations where fire safety is critical, such as industrial plants, commercial buildings, and infrastructure projects. Options like powder-coating and painting are available to meet these regulatory or operational requirements.Q: Where are Perforated Tray Center Reducers commonly applied?

A: They are widely used in industrial, commercial, and infrastructural settings for organized cable management. Their modular compatibility allows integration with various tray system accessories and configurations, maintaining safe and efficient cable distribution.Q: What installation accessories are compatible with these center reducers?

A: The center reducers are compatible with covers, bends, tees, risers, and a wide range of tray fittings, ensuring flexible and comprehensive cable tray systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free