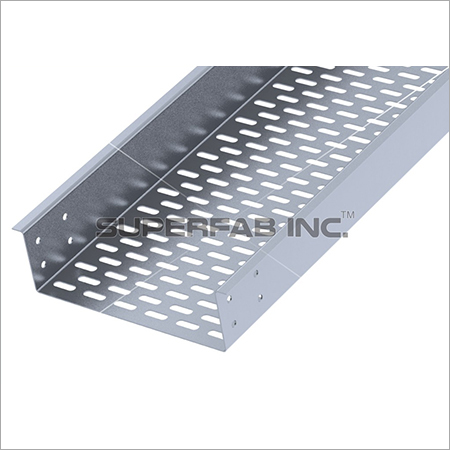

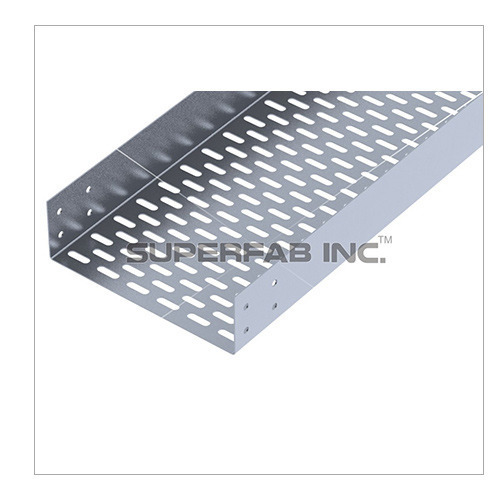

Perforated Cable Tray Inside Flange

Product Details:

- Deflection 5 mm at max. load

- Surface Finish Galvanized / Powder Coated / Painted (as specified)

- Max. Working Load Up to 125 kg/metre (depending on tray specification and support spacing)

- Conductor Material Steel (Galvanized or Stainless as per requirement)

- Product Type Perforated Cable Tray with Inside Flange

- Material Pre-Galvanized Steel / Hot Dip Galvanized / Mild Steel / Stainless Steel (as per requirement)

- Standard Thickness 1.2 mm to 3.0 mm

- Click to View more

X

Perforated Cable Tray Inside Flange Price And Quantity

Perforated Cable Tray Inside Flange Product Specifications

- 2500 mm x (selected width) x (selected side height)

- 1.2 mm to 3.0 mm

- 50 mm to 900 mm (Customizable)

- Up to 125 kg/metre (depending on tray specification and support spacing)

- Galvanized / Powder Coated / Painted (as specified)

- Pre-Galvanized Steel / Hot Dip Galvanized / Mild Steel / Stainless Steel (as per requirement)

- Steel (Galvanized or Stainless as per requirement)

- 2500 mm (Standard)

- Perforated Cable Tray with Inside Flange

- As per size and material (varies by specification)

- 15 mm to 150 mm

- 5 mm at max. load

- Silver / Grey (metal finish)

Product Description

We have carved a niche in this domain as a topmost manufacturer, exporter and supplier of Perforated Cable Tray Inside Flange. This tray is manufactured using quality approved raw materials and pioneering techniques by dexterous professionals. Ideal for keeping wires and cables on it for proper laying around the premises, this tray is highly appreciated among customers. Moreover, we offer this Perforated Cable Tray to our prestigious clients at reasonable rates within committed delivery time.

Key Points:

- Fine finish

- Accurate dimensions

- Corrosion resistance

- Highly durable

Specification

| Length (Meters) | 2.5/3 |

| Width (MM) | 50 1200 |

| Height (MM) | 15 150 |

| Thickness (MM) | 1 3 |

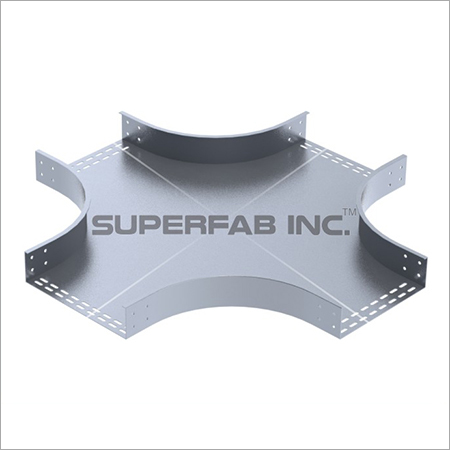

Perforated Cable Tray Technical Diagram :

.jpg)

Superior Corrosion Resistance

Crafted from pre-galvanized steel, hot dip galvanized, mild steel, or stainless steel, this cable tray offers exceptional resistance to corrosion. Its surface finish optionsincluding galvanized, powder-coated, or paintedfurther prolong durability, making it ideal for harsh industrial or outdoor applications.

Flexible Installation and Modularity

The inside flange design allows for wall, floor, or suspended ceiling mounting. Trays are supplied in standard 2500 mm lengths and customizable widths from 50 mm to 900 mm, ensuring adaptability for different project requirements. Modular assembly makes on-site installation fast and efficient.

Comprehensive Cable Management Solution

Perforated slots provide effective cable ventilation, minimize overheating, and support organized routing for diverse installationsfrom power to data and telecommunications. With available accessories such as covers, clamps, support brackets, coupler plates, and dividers, every cable management need is addressed.

FAQs of Perforated Cable Tray Inside Flange:

Q: How is the Perforated Cable Tray Inside Flange installed?

A: Installation is modular and straightforward. The tray can be wall-mounted, floor-mounted, or suspended from the ceiling using compatible brackets and supports. Coupler plates and clamps are supplied to assist with secure assembly and connection.Q: What are the benefits of using standard elongated/perforated slots in these trays?

A: The elongated slots enhance ventilation, helping prevent cable overheating, and facilitate easy cable entry and exit for organized management. They are suitable for both electrical and data cables in demanding environments.Q: When should I choose high corrosion-resistant material for my cable tray?

A: High corrosion-resistant materials like hot dip galvanized or stainless steel are recommended for industrial and outdoor environments where exposure to moisture, chemicals, or harsh conditions is expected, ensuring a longer service life.Q: Where can these cable trays be used effectively?

A: They are ideal for electrical, data, and telecom installations in factories, plants, commercial buildings, and outdoor setups. Their compliance with IS 1079/IS 513 & IEC standards assures safe and reliable performance.Q: What is the process for selecting the correct tray specification?

A: Determine the required width (50 mm to 900 mm), side rail height (15 mm to 150 mm), and material based on cable load, environmental conditions, and project needs. Consult with the supplier for customized solutions and accessory selection.Q: How long is the expected service life of the cable tray under normal conditions?

A: Under typical operational conditions, the tray offers a service life between 10 to 15 years, thanks to its robust material options and protective finishes.Q: What accessories are available and how do they improve usage?

A: Accessories such as covers, clamps, support brackets, coupler plates, and dividers are available. They enhance safety, maintain cable separation, provide secure mounting, and facilitate modular assembly for a tailored cable management solution.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free