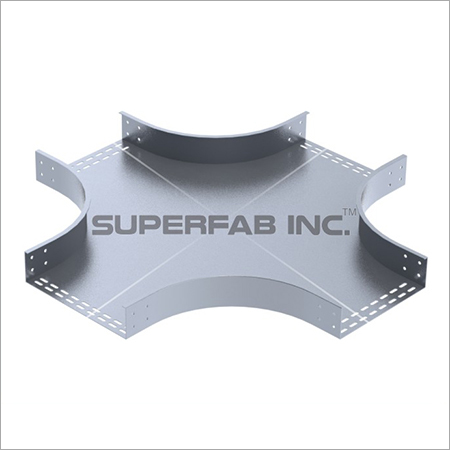

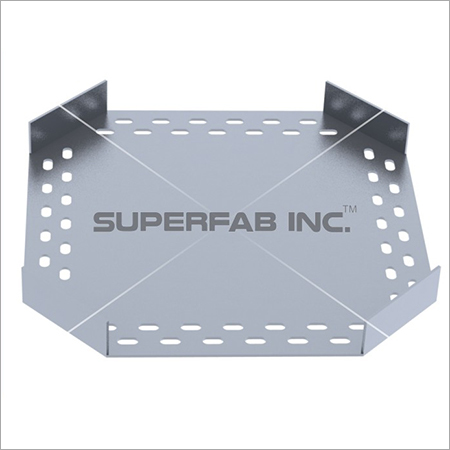

Perforated Tray Tee

Product Details:

- Max. Working Load Up to 100 kg/m, varies with tray size and material

- Deflection < 6 mm at maximum load

- Conductor Material Galvanized Iron / Mild Steel / Stainless Steel / Aluminum

- Surface Finish Pre-Galvanized, Powder Coated, Hot Dip Galvanized, Painted

- Product Type Perforated Tray Tee

- Material Pre-Galvanized Steel, Mild Steel, Stainless Steel, Aluminum

- Standard Thickness 1.2 mm, 1.6 mm, 2 mm, or as specified

- Click to View more

X

Perforated Tray Tee Price And Quantity

Perforated Tray Tee Product Specifications

- Customizable as per project needs

- 1.2 mm, 1.6 mm, 2 mm, or as specified

- Depends on size and material (varies accordingly)

- As per requirement (commonly available in 2.5m or 3m)

- 25 mm to 150 mm

- Perforated Tray Tee

- < 6 mm at maximum load

- Up to 100 kg/m, varies with tray size and material

- Pre-Galvanized Steel, Mild Steel, Stainless Steel, Aluminum

- Galvanized Iron / Mild Steel / Stainless Steel / Aluminum

- Pre-Galvanized, Powder Coated, Hot Dip Galvanized, Painted

- Metallic Silver / Custom Coating Available

- 50 mm to 900 mm

Product Description

Supported by our adroit team of professionals, we have been engaged in manufacturing, exporting and supplying a finest array of Perforated Tray Tee. This tee is manufactured using supreme grade raw materials and sophisticated techniques by dexterous professionals. Suitable for connecting cables in a secure way, this tee is highly cherished among customers. The provided tee is examined on various quality parameters prior dispatch to ensure its superior finish and non corrosive nature. This Perforated Tray Tee can be availed from us at pocket friendly rates.

Key Points:

- Easy installation

- Dimensionally accurate

- Sturdiness

- Lightweight

Specifications:

- Radius (mm): 300, 600, 800, 900, 1000, 1200

- Width (mm): 50 - 1200

- Height (mm): 15 - 150

- Thickness (mm): 1 - 3

Versatile Material and Size Options

Available in pre-galvanized steel, mild steel, stainless steel, and aluminum, the Perforated Tray Tee can be tailored in width (50900 mm), side rail height (25150 mm), and standard thickness (1.2 mm, 1.6 mm, 2 mm, or custom). Customizable lengths and dimensions ensure compatibility with different site layouts and load requirements.

Corrosion and Fire Protection for Safety

Engineered to comply with industrial fire safety standards, this tray tee provides high-level fire resistance. Various surface finishes such as powder coating, hot-dip galvanizing, painting, and pre-galvanizing ensure excellent corrosion protection, supporting reliable long-term use even in harsh environments.

Flexible and Secure Installation

Bolt-on installation combined with clamp/fastener provisions allows quick, reliable setup. The tray tee integrates seamlessly with cable tray covers, couplers, fasteners, and cable clamps for comprehensive cable management solutions. Installation is straightforward, reducing project downtime and ensuring operational efficiency.

FAQs of Perforated Tray Tee:

Q: How is the Perforated Tray Tee installed in a cable management system?

A: The tray tee is installed using a bolt-on method with clamp or fastener provisions. This setup ensures secure attachment to cable trays and accessories, facilitating easy and reliable connection at branching points within the cable routing network.Q: What are the benefits of the standard slot and hole perforation pattern?

A: The slot and hole perforation enhances cable ventilation, reducing heat build-up and supporting safe operation. It also simplifies cable fixation and organization, allowing for straightforward cable tie or clamp attachment during installation.Q: When should I use a 90-degree bend tray tee in my project?

A: A 90-degree bend tray tee is ideal when branch-off is required from the main cable tray at right angles, commonly used in complex layouts involving multiple cable runs or when organizing cables for efficient distribution.Q: Where can the Perforated Tray Tee be applied?

A: It is suitable for various environments, including industrial facilities, commercial buildings, data centers, and manufacturing plants, where cable management for power, control, instrumentation, and communication is essential.Q: What process ensures corrosion and fire resistance in the tray tee?

A: Corrosion resistance is achieved through surface finishes such as pre-galvanizing, powder coating, hot-dip galvanizing, or painting. Fire resistance is ensured by compliance with industrial fire safety standards, protecting cables in critical installations.Q: How do I select the correct size and material for my tray tee?

A: Size and material selection depends on cable volume, environmental conditions, load requirements, and project specifications. Common options include widths from 50 mm to 900 mm and materials like pre-galvanized steel, mild steel, stainless steel, and aluminum.Q: What accessories are compatible with the Perforated Tray Tee?

A: The tray tee integrates with cable tray covers, couplers, fasteners, and cable clamps. These accessories support complete cable management solutions while promoting safety and ease of maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free