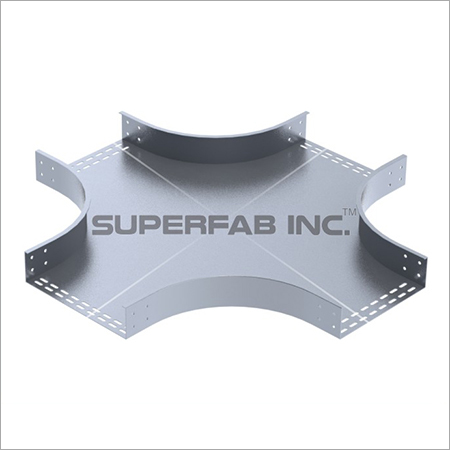

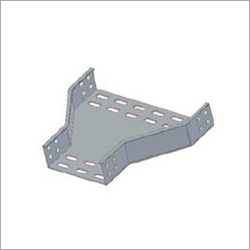

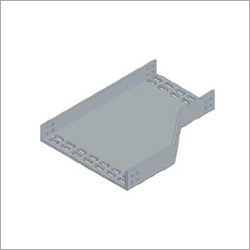

Perforated Tray Vertical Bend Inside

Product Details:

- Deflection Within permissible range as per IS/IEC standards

- Max. Working Load Up to 80 Kg/m

- Surface Finish Galvanized / Powder Coated / Painted / Polished

- Conductor Material Steel / Aluminium

- Product Type Perforated Tray Vertical Bend Inside

- Material Pre-galvanized Steel / Mild Steel / Stainless Steel / Aluminium

- Standard Thickness 1.2 mm, 1.6 mm, 2.0 mm, 2.5 mm

- Click to View more

X

Perforated Tray Vertical Bend Inside Price And Quantity

Perforated Tray Vertical Bend Inside Product Specifications

- Up to 80 Kg/m

- Within permissible range as per IS/IEC standards

- 1.2 mm, 1.6 mm, 2.0 mm, 2.5 mm

- Galvanized / Powder Coated / Painted / Polished

- 50 mm to 900 mm

- Customized as per requirements

- Up to 3000 mm

- Steel / Aluminium

- Silver / Natural Metallic

- Perforated Tray Vertical Bend Inside

- Pre-galvanized Steel / Mild Steel / Stainless Steel / Aluminium

- 25 mm to 150 mm

- Varies as per size and material

Product Description

Being in this domain since 2007, we have been affianced in manufacturing, exporting and supplying a colossal assortment of Vertical Bend Inside Perforated Tray. This tray is used for keeping fiber optic cable and wire in a planned way for proper execution of information. In order to manufacture this tray, our skilled professionals use quality approved raw materials and sophisticated techniques. Our valuable clients can buy this Perforated Tray Vertical Bend Inside from us at competitive rates.Key Points:

- Longer service life

- Dimensionally accurate

- Rugged design

- Corrosion resistance

Product details

| Height (mm) | 15 mm |

| Elbow Bend Angle | 45 Degree |

| Brand | Superfab Inc |

| Material | Steel |

| Cable Tray Coating | Galvanized Coating |

| Width (mm) | 50 mm |

| Thickness | 1 mm |

| Radius (mm) | 300 mm |

Reliable Vertical Cable Management Solution

Experience secure vertical transitions for your cables with this perforated tray bend, engineered for both indoor and outdoor settings. Its customizable length, width, and bend angle ensure adaptability to diverse project requirements, minimizing installation challenges and maximizing reliability.

Premium Materials & Superior Finish

Manufactured from high-quality steel or aluminium, our trays are available in galvanized, powder-coated, painted, or polished finishes. These options assure both aesthetic appeal and outstanding protection against corrosion, extending the products service life in demanding environments.

Safety and Compliance Assured

Every tray comes with de-burred edges to prevent injuries during handling and installation. Adhering strictly to IS 14927 and IEC 61537 standards, our products also offer non-flammable properties, ensuring safety compliance for modern infrastructure projects.

FAQs of Perforated Tray Vertical Bend Inside:

Q: How is the Perforated Tray Vertical Bend Inside used in cable management systems?

A: The tray facilitates efficient routing of cables during vertical transitions, ensuring organized and protected cable layouts in commercial and industrial spaces. It accommodates various installation scenarios both indoors and outdoors.Q: What customization options are available for the trays dimensions and bend angles?

A: You can customize the bend angle (typically 90, but other angles are possible), length (up to 3000 mm), width (50 mm to 900 mm), and side rail height (25 mm to 150 mm) to suit specific project requirements.Q: When should I choose perforated trays with vertical bends for my project?

A: Select these trays when you need to route cables vertically between floors or levels, especially where ventilation, cable fixing, and compliance with international safety standards are priorities.Q: Where can the Perforated Tray Vertical Bend Inside be installed?

A: Thanks to its corrosion-resistant finishes and robust materials, it is suitable for installation in a variety of environments, including both indoor and outdoor areas, such as factories, commercial buildings, and infrastructure projects.Q: What is the installation process for the Perforated Tray Vertical Bend Inside?

A: The trays can be joined using supplied accessories like jointers and fasteners. With de-burred edges and standard perforations, installation is safe, straightforward, and suitable for new or retrofitted cable management networks.Q: What benefits does the perforated pattern provide?

A: The standard perforation pattern enhances air flow for cable ventilation, reduces heat buildup, and makes cable fixing easier by providing multiple points for securing cables, which is critical for maintaining system integrity.Q: Is the product compliant with safety and quality standards?

A: Yes, all trays conform to IS 14927 and IEC 61537 standards, and feature non-flammable properties, ensuring compatibility with rigorous industry regulations and project safety requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free