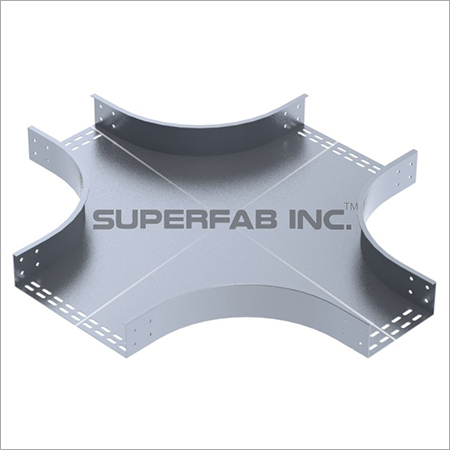

Perforated Tray Horizontal Bend

Product Details:

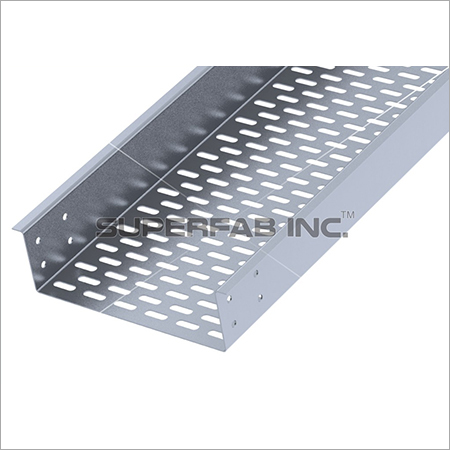

- Conductor Material Metallic (MS/SS/Aluminium)

- Max. Working Load Depends on tray width and support span; generally up to 80 kg/m

- Surface Finish Pre-galvanized, Powder Coated, Hot Dip Galvanized

- Deflection Within standard compliance (<1:100 of span)

- Product Type Perforated Cable Tray Horizontal Bend

- Material Mild Steel, Stainless Steel, Aluminium

- Standard Thickness 0.8 mm to 2.5 mm

- Click to View more

X

Perforated Tray Horizontal Bend Price And Quantity

Perforated Tray Horizontal Bend Product Specifications

- 50 mm to 600 mm

- Metallic (MS/SS/Aluminium)

- Depends on tray width and support span; generally up to 80 kg/m

- Mild Steel, Stainless Steel, Aluminium

- Up to 3000 mm

- 0.8 mm to 2.5 mm

- Perforated Cable Tray Horizontal Bend

- 15 mm to 100 mm

- Custom as per tray size

- Within standard compliance (<1:100 of span)

- Pre-galvanized, Powder Coated, Hot Dip Galvanized

- Varies as per size and material

- Silver/Galvanized/Custom

Product Description

We have gained huge appreciation as a topmost manufacturer, exporter and supplier of supreme quality Perforated Tray Horizontal Bend. This bend is manufactured using top-notch quality raw materials and innovative techniques by dexterous professionals. Ideal for managing cables are wires in a planned way at industries, offices and communication sectors, this tray is highly acclaimed among customers. Furthermore, this Perforated Tray Horizontal Bend can be purchased from us at most affordable rates.

Key Points:

- Supreme finish

- Rugged design

- Lightweight

- Corrosion resistance

Product details

| Sheet Thickness | 3 mm |

| Usage/Application | Perforated Cable Tray Accessories |

| Material | Stainless Steel |

| Brand | Superfab Inc |

| Cable Tray Coating | Hot-Dip Galvanized |

| Elbow Bend Angle | 60 Degree |

Versatile Bend Angles for Complex Cabling Paths

The horizontal bends can be customized to 90, 60, and 45, or any specific angle required by the installation, simplifying the routing of cables around obstacles or corners. This flexibility is essential in environments with complex or irregular layouts.

Durable Material and Superior Protection

Manufactured from mild steel, stainless steel, or aluminium and finished in pre-galvanized, powder-coated, or hot dip galvanized surfaces, these bends ensure exceptional corrosion resistance and cable protection. Deburred edges minimize wear or damage to cables, extending system longevity.

Comprehensive Compliance and Safety

Certified to IS 1079, IS 513, and IEC 61537 standards, the tray bends guarantee fire resistance and operational safety, with a non-flammable metallic body. The life expectancy is approximately 1520 years under standard conditions.

FAQs of Perforated Tray Horizontal Bend:

Q: How do I select the appropriate bend angle for my cable tray installation?

A: The choice of bend angle90, 60, 45, or customshould be based on the layout and specific cable routing needs of your project. These options enable seamless navigation around corners and obstacles, ensuring efficient cable management.Q: What materials are available for the Perforated Tray Horizontal Bend, and what are their benefits?

A: These horizontal bends are manufactured from mild steel, stainless steel, or aluminium, offering options for strength, corrosion resistance, and lightweight installation. Each material is available in various surface finishes, including galvanized and powder-coated, to suit different environments.Q: When is it recommended to use a customized bend angle or fitting?

A: Customized bend angles or fittings are ideal when standard angles do not fit complex site conditions or unique architectural requirements. Customization ensures that cable trays can be routed without excessive stress or bending of cables.Q: Where can the Perforated Tray Horizontal Bend be mounted?

A: This product is designed for wall mounting, floor mounting, or can be custom fitted to match your application needs. Versatile mounting options ensure flexibility for different installation environments.Q: What is the manufacturing process for these tray bends?

A: Tray bends are precision fabricated and CNC punched from sheet metal. This process ensures accurate dimensions, high strength, and smooth, deburred edges for optimal cable protection.Q: How does the horizontal bend protect cables and ensure longevity?

A: The smooth or flanged, deburred edges eliminate sharp surfaces that could damage cables. Combined with high corrosion and fire resistance, the structure ensures a reliable lifespan of 1520 years in regular usage conditions.Q: Are accessories available for connecting and securing the horizontal bends?

A: Yes, a range of accessories including connector plates, couplers, fixings, and covers are available to simplify installation and enhance system stability, ensuring a secure and compliant cable management solution.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Perforated Cable Tray' category

Our Major Market include India - Pune | Hyderabad | Chennai | Bangalore | Noida | Gurgaon | Delhi | Ahmedabad | Indore | JaipurDoha | Lagos | Angola | Johannesburg | Nairobi | Manama | Dubai | Abu Dhabi | Kuwait City | Jakarta | Manila | Hanoi

Call Me Free

Call Me Free